Inventory Management

What is Inventory Management?

Inventory management is the process of overseeing and controlling a company's stock to ensure the right products are available at the right time. It prevents shortages and overstocking, optimizing storage, reducing costs, and improving efficiency. It involves tracking stock, forecasting demand, and using software for automation. Effective inventory management is crucial for customer satisfaction and business success in industries like retail, manufacturing, and e-commerce.

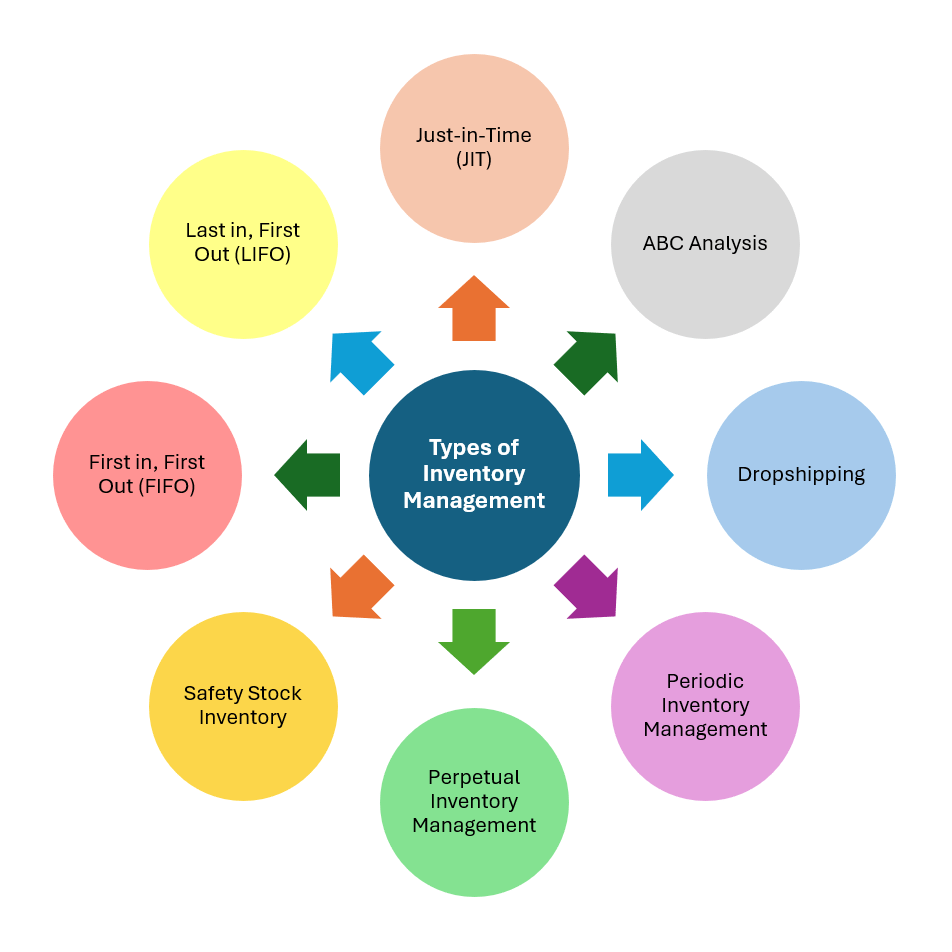

Types of Inventory Management

Businesses employ a range of inventory management systems for efficient stock tracking. Here are several common types:

- Just-in-Time (JIT): Minimizes excess stock by ordering inventory only when needed, reducing carrying costs.

- ABC Analysis: Categorizes inventory into ‘A’ (high-value), ‘B’ (moderate-value), and ‘C’ (low-value) items to prioritize management efforts.

- Dropshipping: Retailers don’t stock products but buy them from a third party when sold, reducing inventory maintenance.

- Periodic Inventory Management: Manual stock counts at set intervals, suitable for businesses with simpler product ranges.

- Perpetual Inventory Management: Real-time tracking using technology like barcode scanning or RFID for immediate insights into stock levels.

- Safety Stock Inventory: Maintains extra inventory as a buffer to handle unexpected demand or supply disruptions.

- First in, First Out (FIFO): Sells the oldest inventory first, ideal for perishable goods.

- Last in, First Out (LIFO): Sells the most recently acquired inventory first, useful for managing costs or tax liability.

By implementing the right type of inventory management system, businesses can streamline their operations, reduce costs, and ensure optimal levels of stock to meet customer demand efficiently.

Benefits of Inventory Management

• Optimal Stock Levels: Prevent overstocking and shortages to meet customer demand.

• Reduced Holding Costs: Minimize warehousing and insurance expenses.

• Improved Order Fulfillment: Enhance customer satisfaction and loyalty.

• Enhanced Cash Flow: Free up funds for business growth.

• Minimized Stockouts: Avoid lost sales and maintain a positive reputation.

• Streamlined Operations: Improve workflow efficiency and organization.

• Accurate Demand Forecasting: Plan production and resources efficiently.

• Effective Cost Control: Control rush order and storage costs for competitive pricing and higher profit margins.

Process of Inventory Management

Inventory management is the process of overseeing and controlling the flow of goods and materials within a company’s operations. It involves managing the quantities of various products, ensuring that the right items are available in the right quantities, and at the right time. The primary goal is to strike a balance between having enough inventory to meet customer demand while avoiding unnecessary overstocking, which can lead to increased storage costs and wastage.

The process typically involves several key steps:

Stock Monitoring: Regularly tracking inventory levels to meet demand and prevent stockouts.

Ordering and Restocking: Replenishing inventory through timely supplier orders.

Categorizing Inventory: Prioritizing management by classifying items based on factors like demand and value.

Inventory Tracking Systems: Using technology for real-time tracking and insights into stock availability.

Forecasting and Demand Planning: Predicting demand and optimizing stock levels based on historical data and market trends.

Quality Control: Ensuring incoming inventory meets quality standards.

Optimizing Storage Space: Efficient storage organization to prevent product obsolescence.

Regular Audits and Analysis: Analyzing data and KPIs for informed decision-making and effective strategies.

Inventory Management Techniques and Terms

- Just-in-Time (JIT): Orders inventory as needed to reduce storage costs.

- ABC Analysis: Categorizes inventory into ‘A,’ ‘B,’ and ‘C’ items based on importance.

- EOQ (Economic Order Quantity): Calculates the ideal order quantity to minimize costs.

- Safety Stock: Extra inventory to prevent stockouts due to uncertainties.

- Lead Time: Time from order placement to inventory receipt.

- FIFO (First-In, First-Out): Oldest stock used first to reduce obsolescence.

- LIFO (Last-In, First-Out): Uses most recently acquired goods first, often for pricing or tax purposes.

- Reorder Point: Inventory level triggering a new order to maintain supply.

Challenges of Inventory Management

Inventory management can present several challenges for businesses, affecting their overall operations. Some common challenges include:

- Overstocking and understocking, impacting costs and customer satisfaction.

- Inaccurate demand forecasting causing supply-demand imbalances.

- Poor visibility and control across multiple locations.

- Supply chain disruptions leading to stockouts.

- Technological limitations hindering accurate tracking and order management.

- Seasonal demand variations causing stock imbalances.

- Rising holding costs eating into profits.

- Quality control issues leading to inventory wastage.

- Demand volatility from changing customer behavior.

- Lack of automation causing inefficiencies and errors. Addressing these challenges is crucial for optimizing inventory management and overall operational efficiency.

- Effectively addressing these challenges is crucial for businesses to optimize their inventory management, reduce costs, and enhance overall operational efficiency. Employing advanced technologies and implementing robust inventory management strategies can help businesses navigate these challenges more effectively.

Future of Inventory Management

The future of inventory management looks promising, with several exciting advancements on the horizon. As technology continues to evolve, businesses can expect more streamlined and efficient processes to manage their inventory effectively. Some key elements that define the future of inventory management include:

- Automation and AI: AI-driven systems for demand prediction and error reduction.

- Real-Time Inventory Tracking: IoT and tracking systems for transparent, stock monitoring.

- Data Analytics: Predictive insights for adapting to demand and supply chain changes.

- Cloud-Based Solutions: Flexible, collaborative inventory management across locations.

- Blockchain Integration: Enhanced security, transparency, and traceability.

- Sustainable Practices: Eco-friendly inventory strategies for an environmentally responsible supply chain.

As businesses continue to embrace these technological advancements and sustainable practices, the future of inventory management holds the promise of improved efficiency, enhanced customer experiences, and a more resilient and adaptable supply chain. Embracing these trends will be crucial for businesses to stay competitive and thrive in an increasingly dynamic and interconnected global marketplace.

Pluugin's Significance in Optimizing Business Inventory

Pluugin streamlines inventory management, enhancing efficiency and satisfaction. It tracks inventory, automates updates, and ensures balanced supply. Forecasting and order integration prevent understocking and excess inventory. Pluugin optimizes warehouses, offers detailed analysis, and integrates with e-commerce platforms. Its scalability suits businesses of all sizes, promoting growth and competitiveness. Contact us for improved inventory control